Cleaning the Durst P10

At work this week I am doing training to learn how to use a

printer this weekend I learnt how to clean the printing heads

for a Durst P10 this printer has approx 24 heads it prints in

4 colours. It is possible to print more than 4 such as Light,

Cyan and Magenta and also white.

A head consists of 4 shoots this is where the ink is printed from

the ink is pushed through the shoots to create the tiniest of

bubbles of which is then suspended in air - in order for

this to work the ink must be heated (In the reservoir) otherwise

it won't print. At the wrong temperature the ink can be either

too thin or too thick producing bad prints. If the machine has been

stood not in production for a long time it is necessary to do what

they call a 'purge' this reheats the ink to optimum temprature and

releases the ink in the 4 shoots into a waste bucket located under

the machine when you've done this you have to open up the

machine to allow access to the heads you must then wipe the

head clean with a special cloth removing the ink as best of possible

sometimes the ink can be very dry and will need a chemical to

remove it. Once done the machine can be tested to print my first

test came out very wavy which suggested the machine needed a

further clean, in order to print quality the lines must be as straight

as possible this can sometimes be corrected by printing a dummy

image and then re trying the test they keep the tests at work to

keep the machine in warranty.

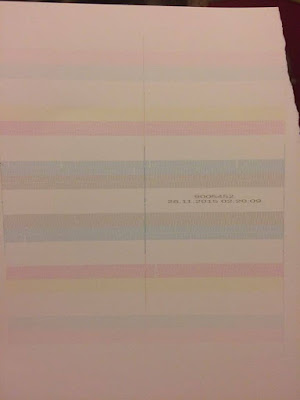

The Durst P10 is relatively small but for example if the same

testing process was done on a much larger printer the test sheet

can be over a metre long - the test sheet is an image of all the

heads in the image shown there is more than 3x the amount

of heads on the 'Inca'

Colour Management

Basically when we as designers want to use a pantone colour

each printer will recognise the pantone colour and create a

4 colour separation with a percentage of colour, your artwork will

be sent through a colour management programme such as a GMG

which is a series of settings so the printer can print the pantone colour

with correct settings usually created by the printer. Every printer

uses different inks so this can pose a problem when creating consistency

this is why Panotone books are necessary in a printers, this weekend

I corrected around 20 pantone colours to print exactly the same as

the pantone colour it says (On different machines). To do this you

must painstakingly print many copies and adjust the percentages until

perfect otherwise all machines will print a different version of the colour

you then cannot guarantee consistency which is important for campaigns.

Although some colours will be set up in one machine they may not be in

others it can take hours and even days to correct colours - The colours

I corrected were for a waitress campaign this took me 4 hours and still

3 colours still need to be amended.

For example if the colour is too light compared to the pantone swatch you

could add a percentage of black? you must always remember how much

you add the calculation as there is a chance you will need to reset it back

to the colour, although the machine I was using was for colours some

have way more which can complicate the colour management further.